Past Projects

Past projects led by Dr. Cale include:

Power, Power Electronics, and Feedback Controls

- Modeling lead at NREL for the facility microgrid conceptual design at US Marine Corps Miramar. Work included: modeling all distribution loads based on SCADA measurement data, modeling the distribution system (lines, substation, transformers), modeling the PV inverter systems, and performing dynamic electrical studies for the base. Reference.

- Modeling lead at NREL for a (grid-forming) energy-storage based minigrid at US Marine Corps Miramar. Work included: modeling the energy storage system, PV and associated power electronics, modeling the PI loop control for grid-forming operation, and validating the system performance in simulation. Reference.

- Extensive experience designing, building, and simulating power electronic converters such as buck, buck-boost, controlled and line-commutated rectifiers, full-bridge inverters, and power amplifier circuits. Tools used: MATLAB/Simulink, PSCAD, C/C++.

Reference.

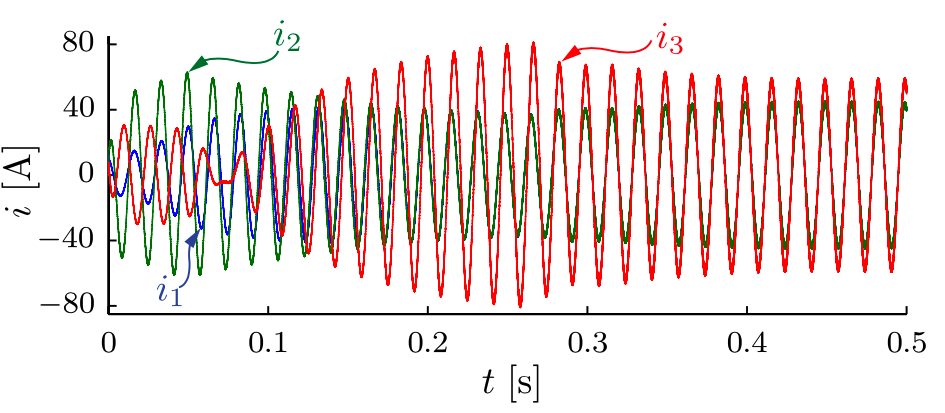

Synchronization of phase currents using a grid-forming microgrid control scheme. - Designed and implemented a new hardware-in-the-loop system for evaluating PI loop control strategies for utility-scale photovoltaic inverters. These evaluations were done using the inverter control boards to evaluate firmware algorithms before testing on the inverter units at full power. Tools used: National Instruments, C/C++, LabView.

- Developed (with colleagues) a novel approach for mitigating communication delays between geographically distributed hardware-in-the-loop systems using an advanced embedded observer technique. Tools used: Opal-RT HIL, Arduino. Reference.

Design Optimization & Trade-off Analysis

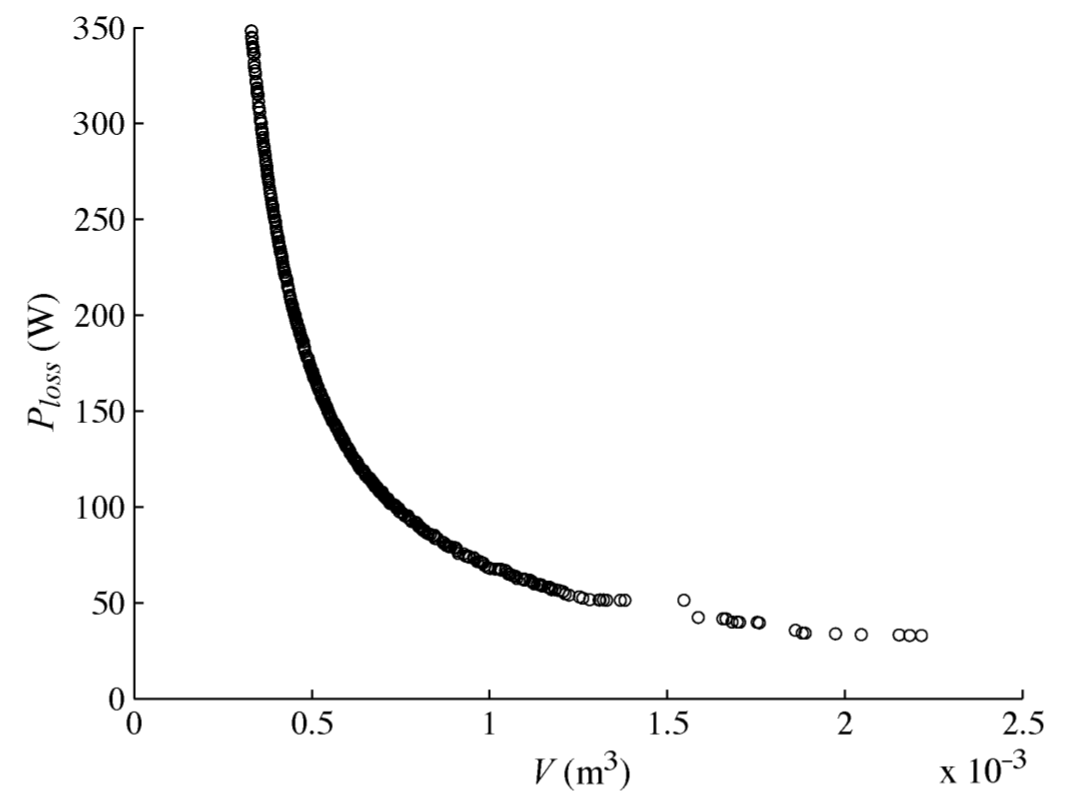

- Design trade-off studies: Analysis of the trade-offs between volumetric power density and design cost. Tools used: genetic algorithms, Pareto-optimality.

Reference.

Pareto-optimal front: loss vs. volume. - Parameter identification: Based on measurement data, the selection of the best-fit parameters to a derived mathematical representation. Tools used: genetic algorithms. Reference.

- Real-time resolution of optimal operation: Numerical operator to adjust an optimal design solution based on new information, e.g., field measurements. Tools used: particle swarm optimization. Reference.

Data Analytics

- Design, installation and verification of real-time part classification and rejection of parts on a high through-put manufacturing line: Based on analysis of past system performance, the manufacturing process of a critical component was embedded with multiple sensor types (e.g., fuel cells, LVDT probes) to obtain measurement of real-time process data. Using statistical techniques and pattern recognition, a machine learning algorithm was implemented to automate a part pass/fail mechanism. Tools used: machine learning, National Instruments, C/C++, LabView. Reference unavailable (DoD, restricted).

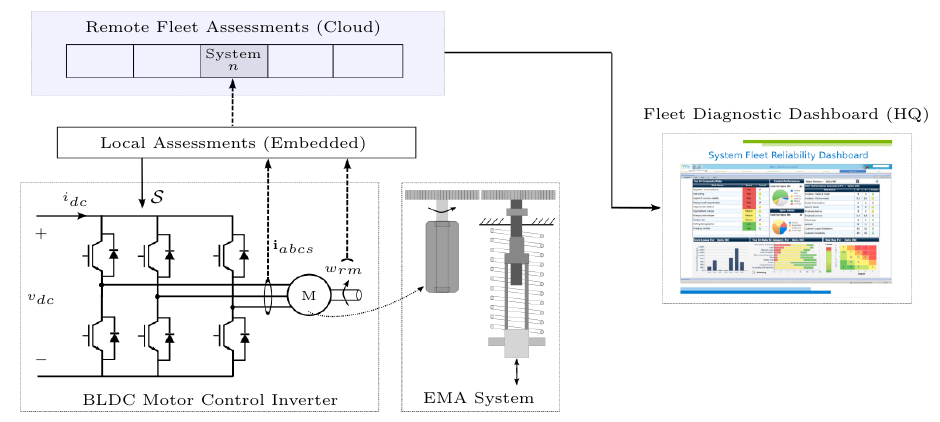

- Real-time, dynamic reliability assessment for a fleet of deployed electro-mechanical systems: Using component reliability models, an

overall system reliability model, and detailed electromechanical system model derived in this project, a method was employed to dynamically assess

system reliability of electromechanical actuator (EMA) systems after field deployment.

Reference.

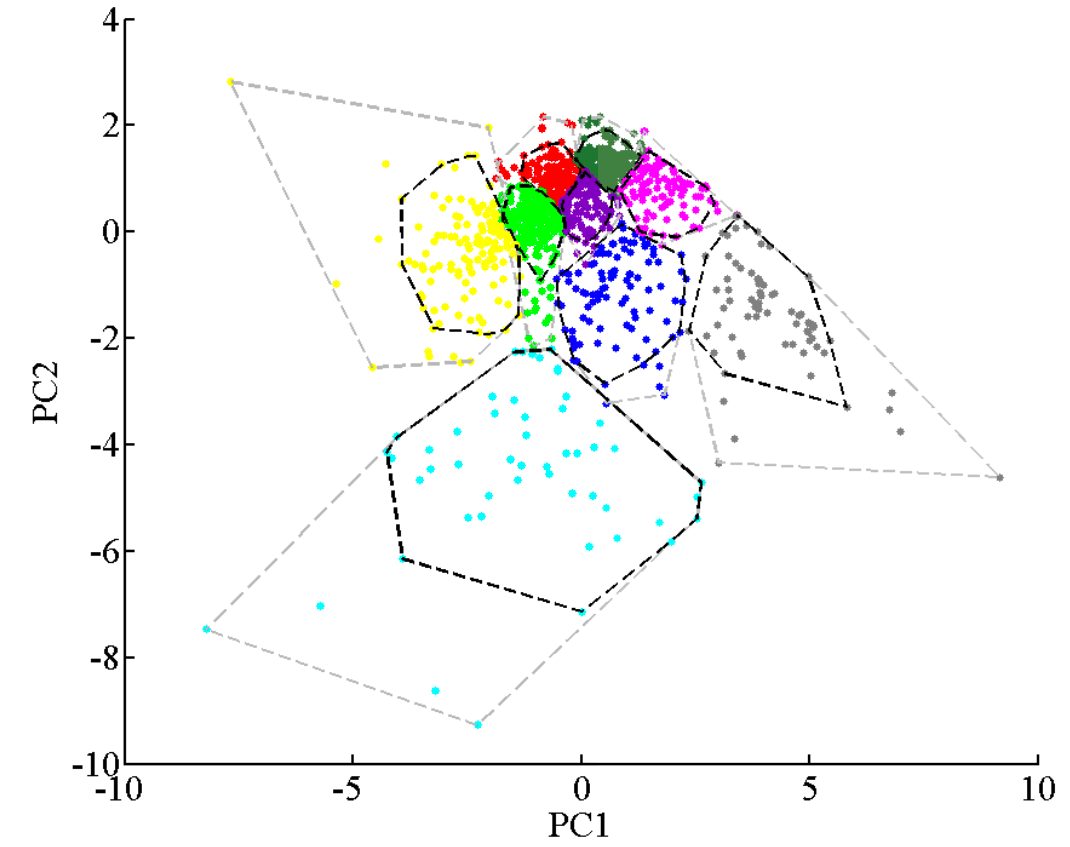

Architecture for dynamic reliability assessment in remote EMA systems. - Classification of large data sets to uncover hidden patterns, for grouping distribution feeder types at an electric utility: From a set of 1200 samples, with 12 data features, the data set was

grouped into intelligible clusters using a statistical method (principle components analysis) and k-means clustering to group the data set.

Reference.

Clustering of a large data set.

Magnetics

- Modeling and characterization of magnetic components: detailed modeling, design and optimization of inductors, transformers, and electrical machinery. Reference.

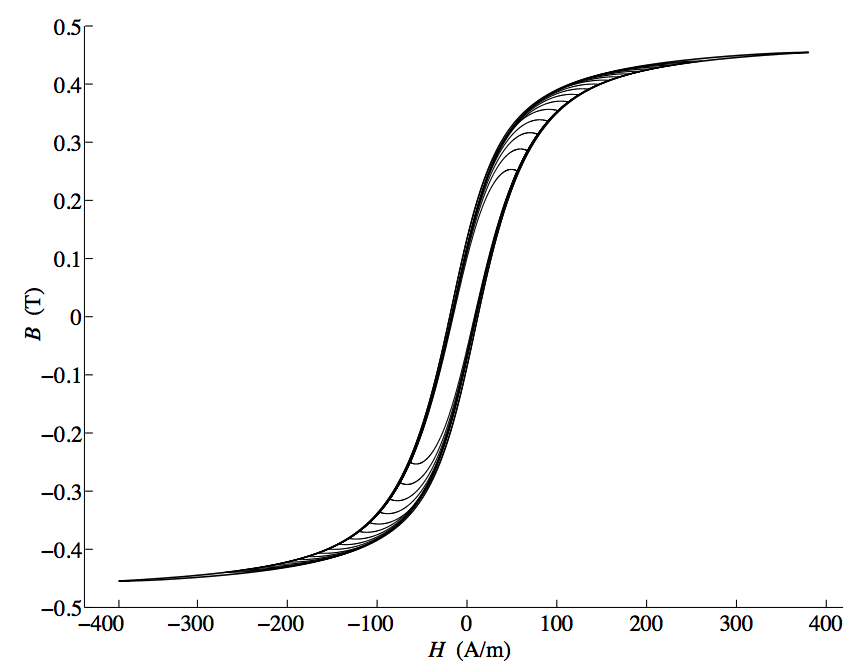

- Magnetic losses: extensive experience modeling magnetic losses in steel and ferrites using approximate and more sophisticated non-linear methods.

Reference.

Magnetic hysteresis loops. - Magnetic finite-element analysis: experience modeling magnetic wave travel and reflection using full-wave magnetic FEA.

Project Management

- Extensive project management experience in both production and research-oriented projects, risk management, and project management software.

- Formal training in Project Management Professional (PMP) methods and practices.

- Formal training in Toyota Production System and Six Sigma.

Working With Us

If would like to discuss a project, please contact us here to inquire about availability and to learn more about our contracting terms. A formal quote on your project will be provided within 3 business days.